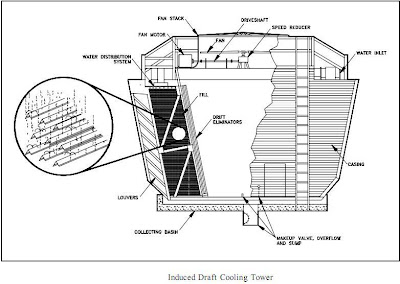

Induced Draft Cooling Towers (part 2)

The nomenclature for induced draft cooling towers, including some items not illustrated in Figure Induced Draft Cooling Tower is summarized below:

Drive shaft - The drive shaft is a device, including couplings, which transmits power from the driver to the speed reducer.

Fan - The fan is a device used to induce air flow through the cooling tower.

Fan deck - The fan deck is a horizontal surface enclosing the top of the cooling tower above the plenum that serves as a working platform for inspection and maintenance.

Fan stack - The fan stack is a cylinder enclosing the fan, usually with an eased inlet and an expanding discharge for increased fan efficiency.

Fill - The fill is PVC, wood, metal, or an alternative material that provides extended water surface exposure for evaporative heat transfer.

Intake louvers - The intake louvers are an arrangement of horizontal blades at the air inlets that prevent escape of falling water while allowing the entry of air.

Makeup valve - The makeup valve is a valve that introduces fresh water into the collection basin to maintain the desired collecting basin water level.

Overflow - The overflow is a drain that prevents the collecting basin from overflowing.

Partition - The partition is a baffle within a multicell cooling tower that is used to prevent air and/or water flow between adjacent cells.

Plenum - The plenum is the internal cooling tower area between the drift eliminators and the fans.

Speed reducer - The speed reducer is a right-angle gear box that transmits power to the fan while reducing the driver speed to that required for optimal fan performance.

Sump - The sump is a depressed portion of the collecting basin from which cold water is drawn to be returned to the connected system. The sump usually contains strainer screens, antivortex devices, and a drain or cleanout connection.

Distribution system - The distribution system is that portion of a cooling tower that distributes water over the fill area. It usually consists of one or more flanged inlets, flow control valves, internal headers, distribution basins, spray branches, metering orifices, and other related components.